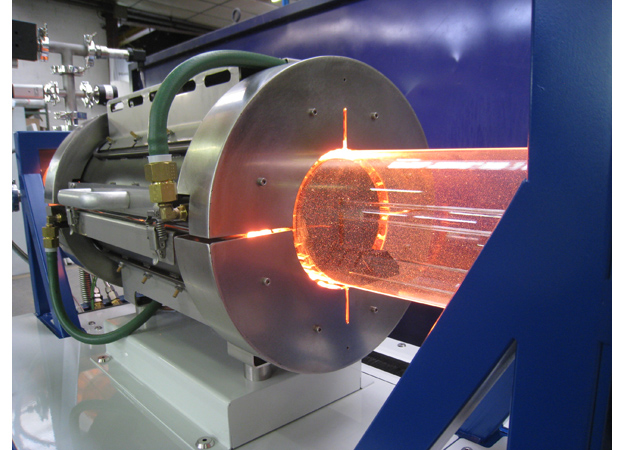

Discover our 900°C Rapid Thermal Process Controlled atmosphere Furnace. Our engineering expertise in heating, atmosphere management, vacuum management, mechanical transfers, automation and regulation enables us to provide you with a solution that is perfectly adapted to your needs.

We adapt to your expectations by providing you with numerous solutions for research laboratories or industrial production.

All our equipment is CE compliant and is manufactured with materials that comply with current legislation.

| Caractéristiques (Fr) | Specifications (Eng) | |||

|---|---|---|---|---|

|

Atmosphère de travail Process |

Air Atmosphère contrôlé vide *selon température et chambre process |

Air Controlled atmosphere vacuum *depending on temperature and process chamber |

||

|

Température Maximale Maximum processing temperature |

Jusqu’à 2200°C |

Up to 2200°C |

||

|

Chambre Process selon température Chamber process |

Métallique, quartz, SiC, céramique ou graphite |

Metallic, quartz, SiC, ceramic or graphite |

||

|

Type de gaz process possible* Process gas type*

*sous réserve compatibilité matériaux, gaz, température *subject to material, gas and temperature compatibility |

Air, azote N2, argon Ar, Hydrogène H2

Autre gaz réducteur sur demande |

Air, Nitrogen N2, argon Ar, hydrogen H2

Other reducing gases on request |

||

|

Pression chambre process possible Process chamber pressure |

Balayage gazeux en légère surpression Régulation de pression inférieur à la Pression Atmosphérique Sous vide |

Gas sweep in slight overpressure Pressure regulation below atmospheric pressure Vacuum |

||

|

Dimensionnement volume utile Sizing |

Jusqu’à 50L |

|

||

|

Volume autre Further sizing |

|

|

||

|

Déplacement de la cloche Top Hat movement |

|

|

||

|

Déplacement du four Furnace movement |

|

Manual or motorised |

||

|

Inclus Included |

Régulateur programmateur classe 0.1 |

Programmable controller class 0.1 |

||

|

Sécurité Security |

Détection de surchauffe |

Overheating detection |

||

|

Ouverture porte |

Furnace opening |

| Caractéristiques (Fr) | Specifications (Eng) | |||

|---|---|---|---|---|

|

Autres options |

|

Dry or wet gas: dew point control |

||

|

Vide primaire ou secondaire |

Medium or High vacuum |

|||

|

|

We are able to offer our clients an end-to-end approach thanks to our technical skills and the experience of our teams.

A unique and advanced technological solution dedicated to the oxidation phase involved in the manufacture of VCSELs